-

About UsZHONGTAI HENGBANG Engineering Technology Co., Ltd. is located in the Academician Entrepreneurship Base of Tai'an National High-Tech Industrial Development Zone, Shandong Province. The company is a comprehensive service provider specializing in engineering consulting and design, materials R&D and manufacturing, as well as operations and maintenance. With strong technical expertise and robust R&D capabilities, its products are primarily applied in critical areas such as water conservancy infrastructure projects, transportation infrastructure initiatives, and environmental protection solutions for isolating and preventing leakage from urban waste and highly hazardous industrial solid waste.

-

ProductsZHONGTAI HENGBANG Engineering Technology Co., Ltd. boasts production lines sourced from countries including Germany, Italy, Denmark, Belgium, and Switzerland, adhering to rigorous quality management systems and testing standards. We are equipped with advanced testing equipment capable of evaluating tensile strength, creep resistance, UV protection, water permeability, flame retardancy, antistatic properties, chemical corrosion resistance, and oxidation performance.

-

Application CasesThe product is primarily used in hydraulic infrastructure projects, transportation infrastructure projects, and environmental protection applications—including the isolation and impermeability of municipal waste and highly hazardous industrial solid waste.

-

BlogPrioritizing technological advancement and innovation, our company is committed to fulfilling user needs to the fullest extent possible.

Injection-molded Geocell

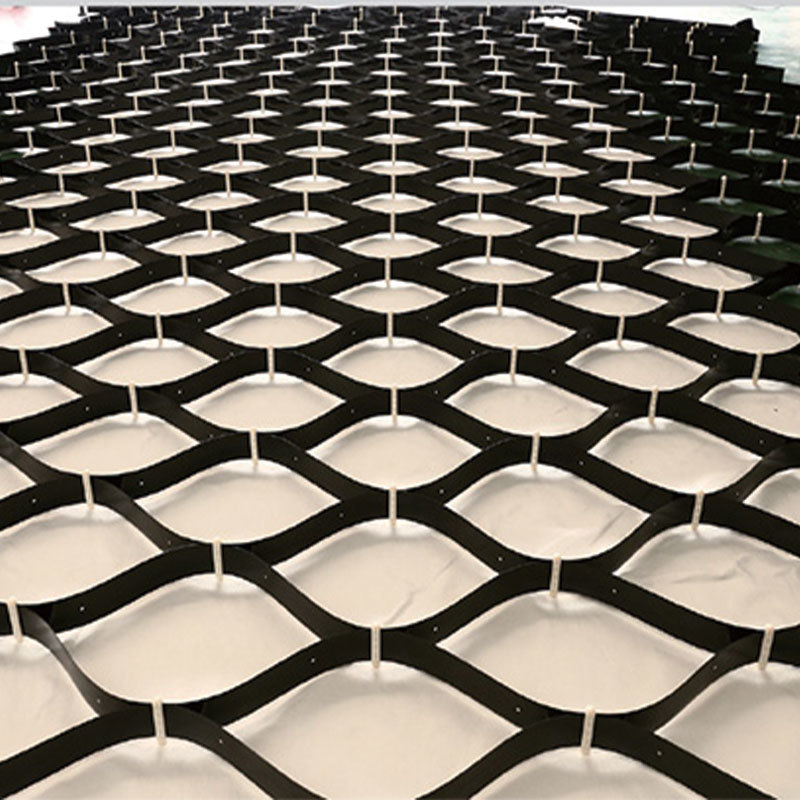

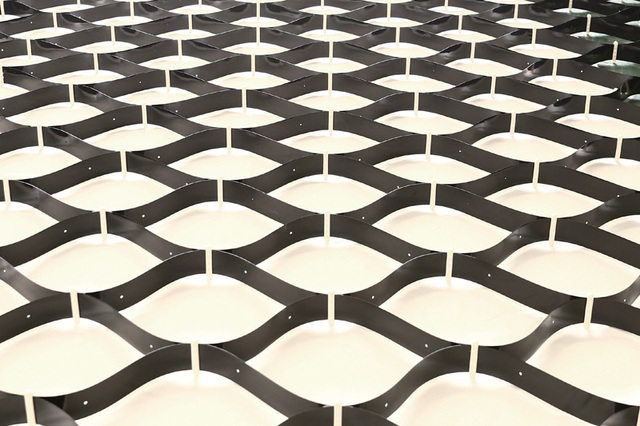

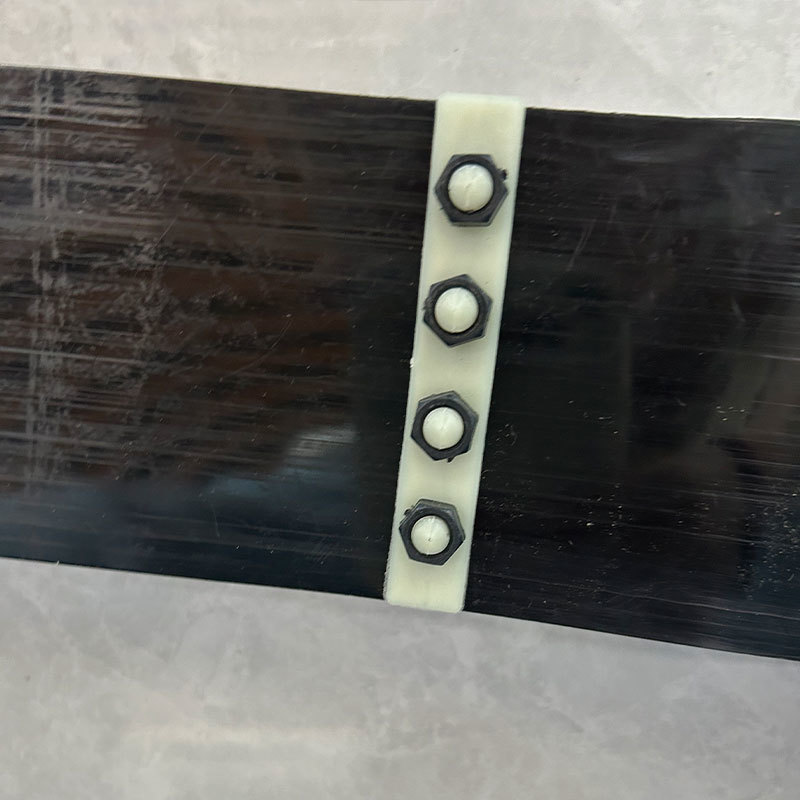

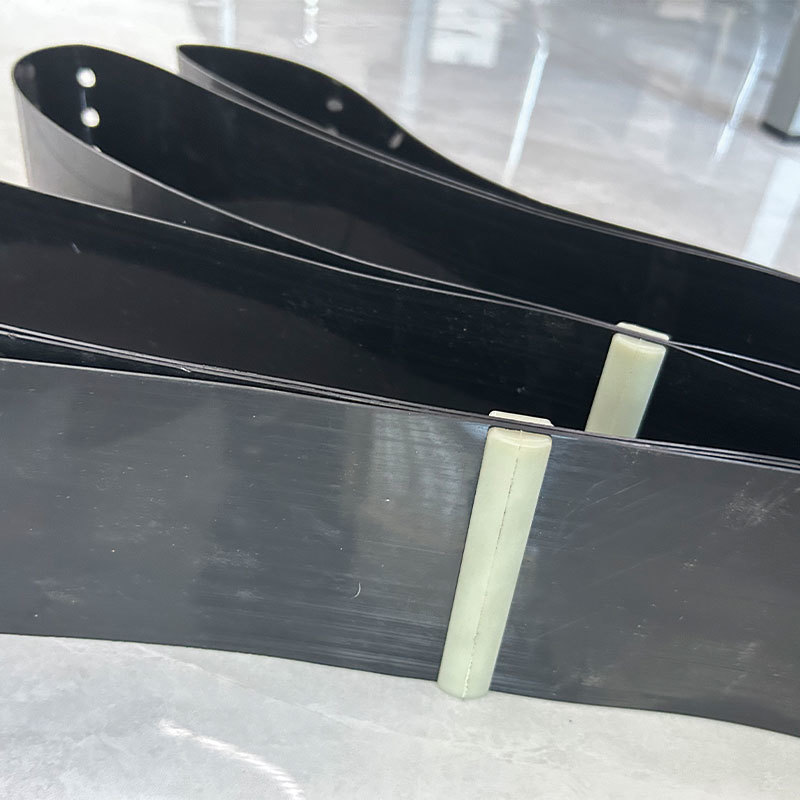

The standard injection-molded geocell is a new product independently developed by our company, designed to meet the diverse requirements of various engineering projects while building upon the foundation of conventional geocells. In addition to retaining the exceptional tensile strength and robust connection points characteristic of standard high-strength geocells, this innovative product also boasts outstanding environmental friendliness and stability. The geocell’s interconnection points are primarily manufactured using advanced injection-molding techniques. Thanks to its all-plastic construction—featuring HPPE and bi-axially oriented high-strength PET—the HPPE/PET injection-molded geocell delivers superior eco-friendly performance. It remains completely non-toxic, even after prolonged contact with acidic or alkaline soil environments, ensuring no contamination of the surrounding ground. Moreover, this material exhibits remarkable resistance to aging, guaranteeing a long service life without compromising structural integrity. Importantly, the durability of the geocell ensures that its performance remains unaffected by potential damage at the connection points. As a result, these geocells can be widely applied in critical infrastructure projects such as railway and highway construction, as well as in challenging terrains like deserts, swamps, tidal flats, airports, ports, and marinas—where soft ground stabilization is essential. They’re also ideal for slope protection, landslide remediation, retaining wall construction, and initiatives aligned with the "Sponge City" concept. Additionally, their versatility makes them perfect for landscaping projects in urban areas and residential communities.

Keywords:

Detailed description

Product Introduction:

The standard injection-molded geocell is a new product independently developed by our company, designed to meet the diverse requirements of various engineering applications while building upon the original geocell design. In addition to retaining the exceptional tensile strength and robust connection points characteristic of conventional high-strength geocells, this innovative product also boasts outstanding environmental friendliness and stability. The geocell’s interconnection points are primarily manufactured using advanced injection-molding techniques. Thanks to its all-plastic construction—featuring HPPE and bi-directional high-strength PET materials—the HPPE and PET injection-molded geocells deliver superior eco-friendly performance. They remain completely non-toxic, even after prolonged contact with acidic or alkaline soils, ensuring no contamination of the surrounding environment. Moreover, these geocells exhibit remarkable resistance to aging, guaranteeing a long service life without compromising their structural integrity. This makes them ideal for a wide range of applications, including soft ground stabilization in railway and highway construction, as well as in challenging terrains like deserts, swamps, tidal flats, airports, ports, and docks. Additionally, they are perfectly suited for slope protection, landslide remediation, retaining wall construction, and even the development of "sponge cities." Beyond infrastructure projects, these geocells can also be effectively utilized in urban and residential green space initiatives, enhancing both functionality and sustainability.

Technical specifications:

Integral Bidirectional High-Strength Injection-Molded Geocell (Tribal Standard) | ||||||||||

Product Model | Tensile strength of the board (≥ N/cm) | Elongation at break (≤) | Right-angle tear resistance (≥ N) | Edge length distance (mm) | Node strength (≥ N/cm) | Tensile strength at component joints (≥ N/cm) | ||||

Vertical | Horizontal | Peel strength | Shear Strength | Tensile strength in tension | ||||||

TGGS50 | 1600 | 15% | 200 | 200 | 150–500 | 600 | 500 | 1600 | 1600 | |

TGGS75 | 1600 | 15% | 200 | 200 | 150–500 | 600 | 500 | 1600 | 1600 | |

TGGS100 | 1600 | 15% | 200 | 200 | 150–500 | 500 | 400 | 1600 | 1600 | |

TGGS150 | 1200 | 15% | 200 | 200 | 150–500 | 500 | 400 | 1200 | 1200 | |

TGGS200 | 1200 | 15% | 200 | 200 | 150–500 | 500 | 400 | 1200 | 1200 | |

Iron-Labelled Geocell Geosynthetic (Q/CR549.1-2016) | |||||||||

Product Model | Tensile Yield Strength of the Sheet Material (≥ MPa) | Sheet thickness (≥ mm) | Yield Elongation (≤) | Right-angle tear resistance (≥ N) | Node distance (mm) | Node strength (≥ N/cm) | Tensile strength at component joints (≥ N/cm) | ||

Vertical | Horizontal | Peel strength | Tensile strength in tension | ||||||

GCE50 | 20 | 0.8/1.1 | 15% | 120/150 | 120/150 | 150–500 | 160 | 320 | 320 |

GCE75 | 20 | 0.8/1.1 | 15% | 120/150 | 120/150 | 150–500 | 160 | 320 | 320 |

GCE100 | 20 | 0.8/1.1 | 15% | 120/150 | 120/150 | 150–500 | 160 | 320 | 320 |

GCE150 | 20 | 0.8/1.1 | 15% | 120/150 | 120/150 | 150–500 | 160 | 320 | 320 |

GCE200 | 20 | 0.8/1.1 | 15% | 120/150 | 120/150 | 150–500 | 160 | 320 | 320 |

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

ZHONGTAI HENGBANG Engineering & Technology Co., Ltd.

Address: East Section of Zhongtianmen Avenue, Tai'an High-tech Zone, Shandong Province

Service Hotline

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.