Plastic drainage ditch

Plastic drainage channels are constructed by wrapping a plastic core with a filter fabric assembly. The plastic core itself is primarily made from thermoplastic synthetic resins, which undergo modification and are then extruded into fine plastic filaments while molten. These filaments are subsequently fused together at their intersection points via a specialized molding device, creating a robust, three-dimensional, mesh-like structure. The plastic core comes in various structural forms, including rectangular, hollow matrix, and hollow circular designs. This innovative material addresses the limitations of traditional drainage systems, offering superior features such as high surface porosity, excellent water collection capabilities, large void spaces, outstanding drainage performance, strong compressive strength, exceptional pressure resistance, remarkable flexibility—allowing it to adapt effectively to soil deformation—and impressive durability. Additionally, its lightweight nature and ease of installation significantly reduce worker labor intensity while boosting construction efficiency. As a result, it has gained widespread popularity among engineering firms and is now extensively used across diverse projects.

Keywords:

Detailed description

11) Drainage systems for low-lying,潮湿 areas. The drainage component of land reclamation projects—plastic blind drains—are internationally recognized as Geosynthetic Drainage Systems (GDS), also referred to as 3D drainage boards or subsurface drainage channels designed for civil engineering applications. These materials are produced by heating and melting thermoplastic synthetic resins, which are then extruded through nozzles to create interwoven fiber strands. These strands are subsequently fused at their intersection points, forming a three-dimensional, highly porous material.

Plastic blind drains are constructed by wrapping a plastic core with a filter fabric. The plastic core itself is primarily made from thermoplastic synthetic resins, which undergo modification and are then extruded into fine plastic filaments while in a molten state—these filaments are forced through nozzles. The extruded filaments are subsequently fused together at their junction points via a specialized molding device, creating a robust, three-dimensional, mesh-like structure. The plastic core comes in various structural forms, including rectangular, hollow matrix, and hollow circular designs. This innovative material addresses the limitations of traditional blind drains, offering superior features such as high surface porosity, excellent water collection, large void spaces, outstanding drainage performance, strong compressive strength, exceptional pressure resistance, remarkable flexibility that accommodates soil deformation, impressive durability, and an ultra-lightweight design. Additionally, its ease of installation significantly reduces worker fatigue and boosts construction efficiency, making it widely favored and extensively adopted across engineering projects.

Product features:

1. The constituent fibers of the plastic drainage ditch are approximately 2mm-thick filaments, fused together at their intersections to form a three-dimensional network structure—its principle is identical to that of trusses used in steel-structure construction. The surface features openings covering 95–97 percent of its area, which is more than five times greater than that of perforated pipes and 3–4 times higher than resin grid tubes, resulting in an exceptionally high surface water absorption rate.

2. Due to its three-dimensional structure, it boasts a porosity rate of 80–95 percent, offering both spaciousness and lightweight design. Moreover, its compressive strength is more than 10 times greater than that of resin-based tube structures. As a result, even if subjected to excessive pressure, the material retains over 50 percent residual void space thanks to its unique 3D architecture, ensuring no blockages in water flow—and eliminating concerns about being crushed by soil pressure.

3. It has high compressive strength, with a compression rate of less than 10 percent even under a pressure of 250 kPa.

4. Equipped with an anti-aging agent, it is highly durable and can remain stable for decades when placed underwater or buried in soil.

5. Resistant to compression yet highly flexible, allowing for construction even in curved areas like bends. It’s also exceptionally lightweight—when backfilling depths are around 10 cm, a bulldozer can even be used for the process.

6. Thanks to the features mentioned above, issues previously encountered with traditional blind drains—such as uneven settlement or partial blockage caused by excessive loads, leading to complete collapse of the voids and subsequent functional disruptions—can now be effectively addressed using plastic blind drain materials.

7. Since the molding process uses hot-melt technology instead of adhesives, there’s no risk of degradation or delamination caused by aging or peeling of the adhesive material.

Application scope:

1) Reinforced drainage for road and railway embankment shoulders;

2) Drainage of tunnels, subway underpasses, and underground freight yards;

3) Soil and water conservation in hillside and slope development;

4) Vertical and horizontal drainage along the sides of various retaining walls;

5) Drainage of the skating area;

6) Drainage from ash ponds at thermal power plants. Drainage from landfill projects;

7) Drainage for recreational and green spaces such as sports fields, golf courses, baseball fields, soccer fields, parks, and other leisure areas;

8) Drainage for rooftop gardens and flower beds;

9) Construction drainage for foundation works;

10) Agricultural and horticultural underground irrigation and drainage systems;

11) Drainage systems for low-lying,潮湿地 areas. The drainage component of land reclamation projects—plastic blind drains—are internationally known as Geosynthetic Drainage Systems (GDS), also referred to as 3D drainage boards or civil engineering-grade subsurface drainage channels. These materials are created by heating and melting thermoplastic synthetic resins, then extruding them through nozzles to form interwoven fiber strands that are subsequently fused at their intersection points, resulting in a three-dimensional, highly porous material.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

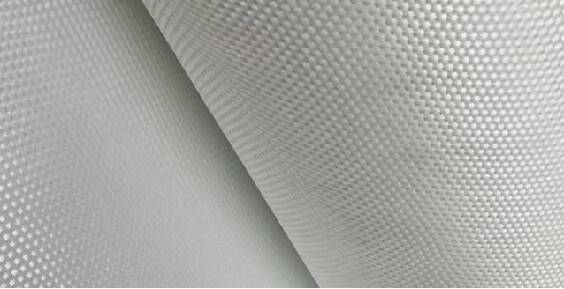

Laminate Film Machine-Woven Fabric