Crack-resistant tape

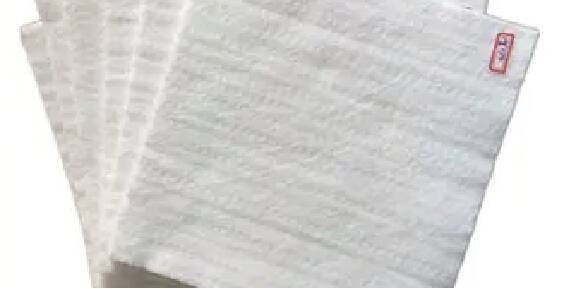

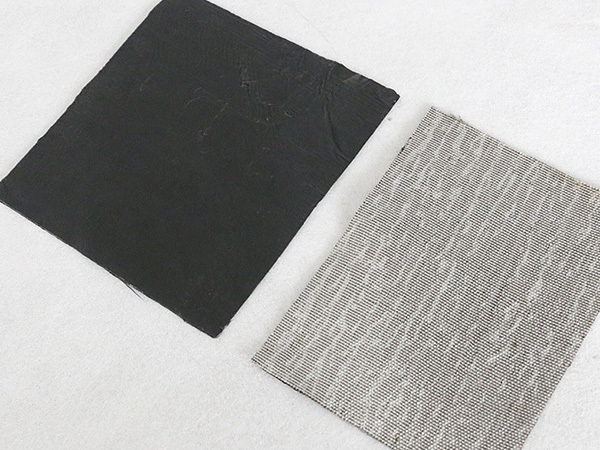

Crack-resistant tape is a roll-type crack-stopping, waterproof membrane made by coating a 2mm-thick polymer waterproof film onto an anti-wrinkle, heavy-load-resistant polypropylene material—and then tightly rolling and compounding the two layers together through a rigorous manufacturing process. This crack-resistant tape features a self-adhesive interlayer that effectively resists cracking and provides superior waterproofing. Its unique structure seamlessly integrates several existing crack- and water-proofing techniques currently used in road construction—such as standalone geosynthetic materials and stress-absorbing layer products—creating an optimized, upgraded solution that combines the best of these approaches for enhanced crack resistance and waterproofing in highway layers.

Keywords:

Detailed description

Product Introduction:

Crack-resistant tape is a roll-type crack-stopping, waterproof membrane made by coating a polymer waterproof film onto an anti-wrinkle, heavy-load-resistant polypropylene material, then tightly rolling and compounding the layers together through a rigorous manufacturing process.

Anti-crack tape is a self-adhesive, interlayer crack-resistant and waterproof material. This innovative structure seamlessly integrates several existing crack- and waterproofing measures—such as geosynthetic materials and stress-absorbing layer materials—currently used individually on highways, representing an optimized, upgraded product that combines the best features of today’s interlayer crack-resistant and waterproofing solutions for roadways.

Product features:

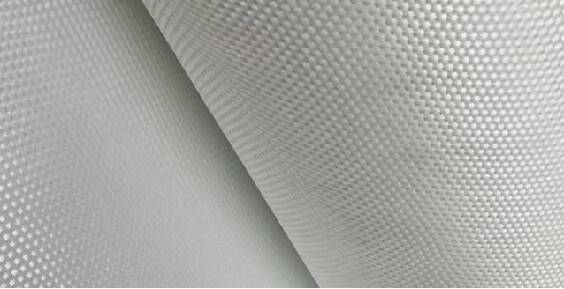

Reinforcement effect: The high-strength, high-temperature-resistant fabric on the surface of the anti-crack tape boasts significant tensile strength, effectively resisting tensile stresses at interlayer cracks and limiting crack width propagation. This reinforcement action enhances the tensile strength of the localized structural layers in asphalt pavements.

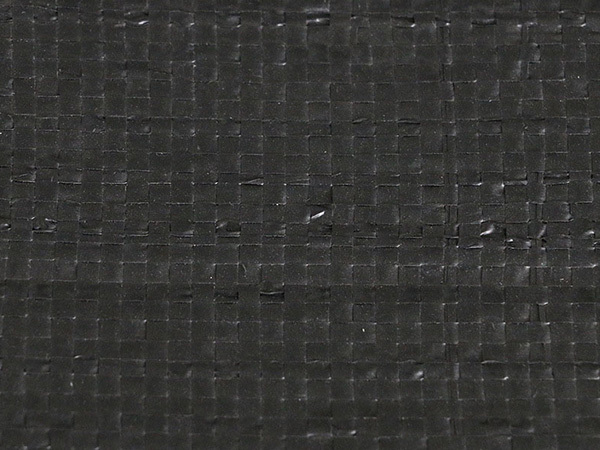

Energy-dissipating buffering effect: The polymers in the anti-crack tape possess both viscoelastic properties and excellent low-temperature flexibility. When applied between asphalt pavement layers, they effectively create a composite layer that maintains its viscoelastic performance even under severe cold conditions. As a result, tensile stresses at crack locations are distributed across this flexible, viscoelastic layer and gradually dissipate over a wider area, helping to absorb and relieve the tensile energy.

Waterproofing and anti-seepage effect: The crack-resistant patch is laid over the surface of interlayer cracks, creating a continuous waterproof and anti-seepage layer that effectively blocks the pathways for rainwater and snowmelt to penetrate, thereby minimizing water damage to the pavement.

Self-adhesive properties: This product features self-adhesion, making construction exceptionally convenient. Simply remove the release liner and directly apply it to the crack area. After gently compacting with a small compaction device, the bond between the material and the pavement becomes even stronger, with no shifting or movement—perfectly meeting the requirements for paving the upper layer of asphalt mix. When applied to asphalt concrete surfaces that have developed cracks or spalling, the crack-resistant tape effectively reduces and isolates the thermal shrinkage stresses acting on the pavement, thereby minimizing the tendency for cracks to reflect upward through the surface layer. By separating the base layer from the upper wearing course, this product ensures that the top layer remains free from multidirectional displacement and shear stresses, making it ideal for use in highways, bridges, and airports.

Product applications:

Crack-resistant tapes are primarily used in new construction and maintenance projects for the pavement bases of highways, general roads, and urban roadways. They feature high tensile strength, excellent toughness, and superior surface adhesion, making them ideal for pavement bases to prevent cracks—caused by temperature fluctuations and vertical loads—from reflecting upward into the surface layer.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric