Hot-melt gasket

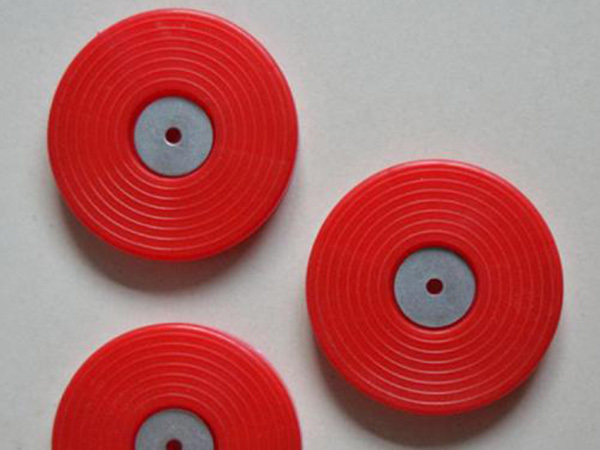

The specialized hot-melt gasket for tunnel waterproofing sheets is a high-performance, thermoplastic component made from a specially formulated mold using high-temperature injection molding of a polymer material (low-density polyethylene), resulting in a precisely sized, circular hot-melt gasket designed specifically for tunnel waterproofing applications (hereafter referred to as the "hot-melt gasket"). This product is primarily used for securing and installing waterproofing membranes, geomembranes, and other waterproofing materials in projects involving water conservancy, highways, railways, and tunnels. Notably, this innovative solution addresses a key drawback of traditional strip-based installation methods—namely, the risk of damaging the waterproofing sheet—while offering significant advantages such as ease of construction, excellent adaptability to irregular excavation surfaces, minimal risk of sheet damage, and lightweight design. As a result, it has gained widespread popularity among engineering professionals.

Keywords:

Detailed description

Product Introduction:

The specialized hot-melt gasket for tunnel waterproofing sheets is a high-performance, thermoplastic component—made from high-density polyethylene (a type of polymer material) through high-temperature injection molding and shaped precisely using a custom-designed mold. These standardized, circular hot-melt gaskets (hereafter referred to as "hot-melt gaskets") are specifically engineered for securing and installing waterproofing membranes in tunnels, as well as in applications involving hydraulic structures, highways, railways, and geotextiles. This product addresses a key limitation of traditional strip-based installation methods, which often risk damaging the waterproofing sheets. In contrast, the hot-melt gaskets offer several advantages: they are easy to install, perfectly adapt to the contours of the excavation surface, minimize the risk of sheet damage, and are lightweight—making them highly favored by construction professionals across the industry.

Installation instructions:

1. Construction Worker: Responsible for guiding the work crew in accordance with design specifications. Technical Lead: Adjusts work methods as needed, based on construction conditions while adhering to design requirements, and provides guidance, oversight, and quality checks during the process. Quality Inspector: Ensures construction quality by verifying compliance with design standards.

2. Construction tools: A hot-air welding and plastic-sealing gun with a maximum power of at least 2 kilowatts, nail guns, nails, hammers, and other similar tools.

Installation: When installing the hot-melt gaskets, arrange them in a plum-blossom pattern. Ensure vertical spacing does not exceed 100 cm, and use at least 5 gaskets per roll of waterproof membrane horizontally. Additionally, maintain longitudinal and transverse spacing of less than 50 cm along the tunnel ceiling. (Use 5 hot-melt gaskets per square meter.) During installation, secure the geotextile to the tunnel excavation surface by using a nail gun to neatly align and fix the hot-melt gaskets both vertically and horizontally. If any steel nail heads protrude, gently flatten them with a hammer to prevent sharp protrusions from puncturing the waterproof membrane.

After the hot-melt gaskets secure the geotextile, 3 to 5 operators begin laying the waterproof membrane. When welding the hot-melt gaskets, start from the bottom and work upward—either clockwise or counterclockwise—using a hot-air welding gun to thermally bond each gasket individually to the back of the waterproof membrane. At this stage, workers should position the waterproof membrane at a 45° angle against the hot-melt gasket, then gently rub the outer surface with their hands to ensure thorough fusion. For the top-layer welding, two operators must carefully support the membrane while simultaneously applying a damp cloth to cool it down, preventing the membrane from slipping or falling before it has fully cooled.

Important notes:

1. When securing the geotextile with hot-melt gaskets, ensure that the nail heads do not protrude, as this could puncture the waterproof membrane.

2. During hot welding, the hot air emitted from the heat-air plastic welding gun should direct 60% of its airflow at a 45-degree angle toward the hot-melt gasket, preventing the waterproof membrane from melting prematurely and thereby avoiding damage to the membrane.

3. The hot-welding time should be controlled within 5 to 10 seconds, depending on the temperature of the hot air emitted by the hot-air welding gun. Operators are encouraged to adjust the melting time according to the actual conditions at the construction site. Importantly, avoid excessively long heating periods to prevent damage to the waterproof membrane, hot-melt gaskets, or geotextiles, which could lead to process defects and unnecessary material wastage.

4. During hot welding, the hot-melt gasket and waterproof sheet should be thoroughly fused together.

5. When welding, do not use a round soldering iron for hot-melt applications.

6. During operation, precautions should be taken to prevent electrical hazards and high-temperature hot air from the welding and plasticizing gun from harming the operator.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric