EVA Waterproof Board

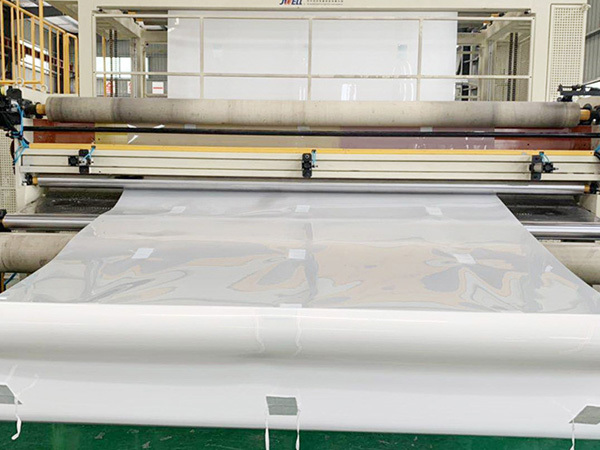

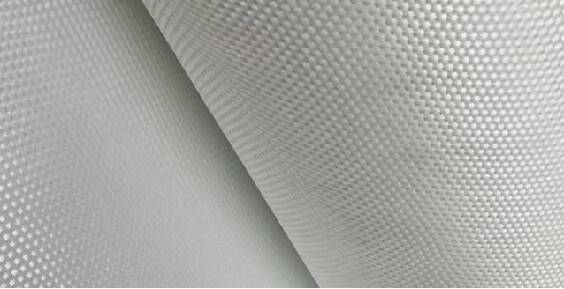

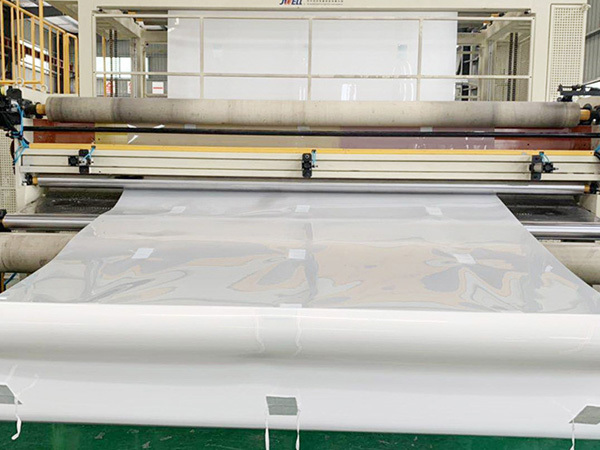

The EVA polymer composite waterproof membrane is a new type of waterproofing material developed by our company, leveraging our robust R&D capabilities. The product is manufactured using an automated rolling-process production line, resulting in a single-step molding process. It is made primarily from high-quality ethylene-vinyl acetate copolymer, with added fibers to enhance strength, modifiers to improve the material’s physical and chemical properties, stabilizers that boost both chemical and physical stability, anti-aging agents to extend the product’s lifespan, antioxidants that enhance its resistance to oxidation, and biocides to prevent bacterial and fungal degradation.

Keywords:

Detailed description

Product Introduction:

The EVA polymer composite waterproof membrane is a new type of waterproofing material developed by our company, leveraging our robust R&D capabilities. The product is manufactured using an automated rolling-process production line, resulting in a single-step molding process. It is made primarily from high-quality ethylene-vinyl acetate copolymer, with fibers added to enhance strength, modifiers incorporated to improve the material’s physical and chemical properties, stabilizers included to boost both chemical and physical stability, anti-aging agents added to extend the product’s service life, antioxidants introduced to enhance its resistance to oxidation, and biocides integrated to prevent bacterial and fungal degradation.

Product features:

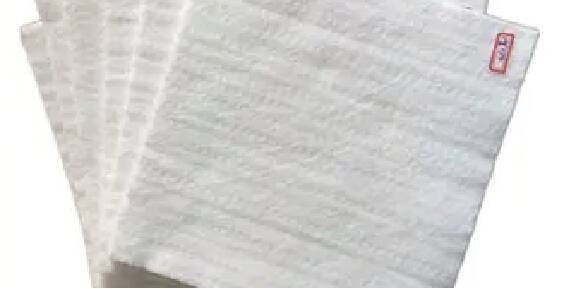

1. We’ve chosen high-quality ethylene-vinyl acetate copolymer—a thermoplastic with rubber-like elasticity—ensuring the finished product boasts excellent flexibility. Handling intricate details like edges, corners, and pipes is remarkably simple and quick.

2. High tear strength, excellent puncture resistance, and good waterproofing, impermeability, as well as superior hydrolysis resistance;

3. Antibacterial agents are specially added to the material to prevent microbial attack, significantly extending the product's shelf life and lifespan.

4. Exhibits excellent root-resistant properties, making it particularly suitable for rooftop gardening;

5. The product exhibits broad compatibility with adhesives and can bond effectively with a variety of adhesive types.

6. There are no specific requirements for the moisture content at the base level. As long as there is no visible water, construction can proceed normally without affecting the quality of the work in any way.

7. Excellent aging resistance, allowing for a service life of over 50 years when buried underground;

8. Exhibits excellent low-temperature flexibility, maintaining good pliability even under -30°C conditions;

9. The product is made from completely non-toxic materials and is an eco-friendly, green product;

Application scope:

Transportation Engineering: Waterproofing and seepage control projects for tunnels, subways, highways, caverns, bridges, and more;

Construction Engineering: Waterproofing and Leak-Proofing for Roofs, Basements, and More.

Hydraulic Engineering: Projects such as reservoir dams, cofferdams, canals, and other structures designed for waterproofing and preventing seepage.

Environmental Engineering: Waterproofing for landfill sites, wastewater treatment plants, metallurgical facilities, chemical plants, and other projects requiring protection against water infiltration, seepage, and moisture.

Construction method:

Preparation Before Laying: Substrate Requirements: Clean the laying surface thoroughly, ensuring the base is smooth and the soil is firm—no unevenness or sharp objects allowed. Waterproof Membrane Welding: Seam treatment is a critical step in construction. Typically, heat welding is used—where the surfaces of the EVA waterproof membranes are heated until they melt, after which pressure is applied to fuse them into a seamless, unified structure.

1. For the laid waterproof membrane, the edges and seams must be free of oil, moisture, dust, and other contaminants.

2. Before welding, ensure the two edges of the film at the joint are properly aligned to achieve a consistent overlap width—typically 70 mm—and that the overlap is smooth and free of wrinkles.

3. Use a dedicated welding machine for welding.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric