-

About UsZHONGTAI HENGBANG Engineering Technology Co., Ltd. is located in the Academician Entrepreneurship Base of Tai'an National High-Tech Industrial Development Zone, Shandong Province. The company is a comprehensive service provider specializing in engineering consulting and design, materials R&D and manufacturing, as well as operations and maintenance. With strong technical expertise and robust R&D capabilities, its products are primarily applied in critical areas such as water conservancy infrastructure projects, transportation infrastructure initiatives, and environmental protection solutions for isolating and preventing leakage from urban waste and highly hazardous industrial solid waste.

-

ProductsZHONGTAI HENGBANG Engineering Technology Co., Ltd. boasts production lines sourced from countries including Germany, Italy, Denmark, Belgium, and Switzerland, adhering to rigorous quality management systems and testing standards. We are equipped with advanced testing equipment capable of evaluating tensile strength, creep resistance, UV protection, water permeability, flame retardancy, antistatic properties, chemical corrosion resistance, and oxidation performance.

-

Application CasesThe product is primarily used in hydraulic infrastructure projects, transportation infrastructure projects, and environmental protection applications—including the isolation and impermeability of municipal waste and highly hazardous industrial solid waste.

-

BlogPrioritizing technological advancement and innovation, our company is committed to fulfilling user needs to the fullest extent possible.

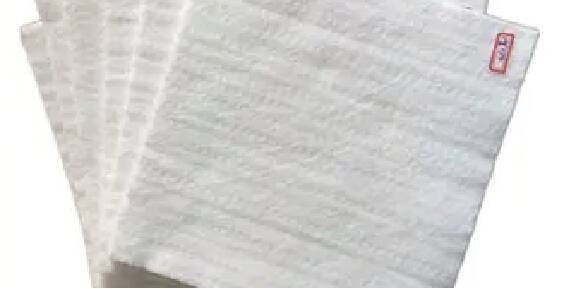

Expansive Soil Waterproof Blanket

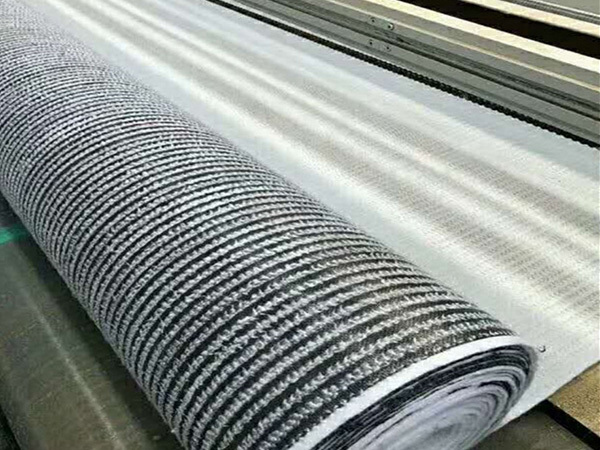

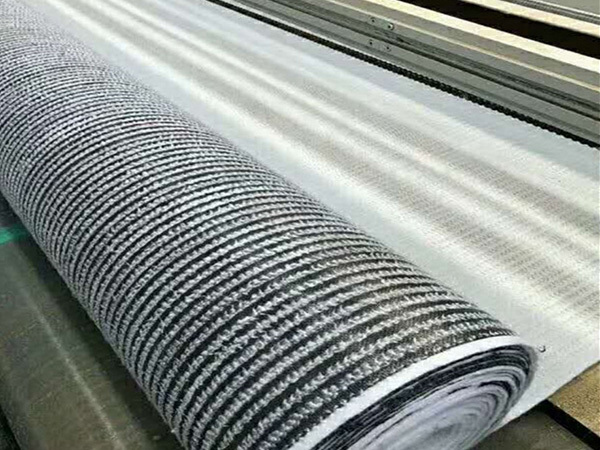

GCL, the Geosynthetic Clay Liner—commonly known as a bentonite waterproof blanket or pad—is a new type of geosynthetic material. It consists of a layer of clay or other low-permeability mineral material encased between geotextile fabric or geomembrane, bonded together through needle-punching or sewing techniques. This eco-friendly, composite, and highly effective barrier material can be further enhanced by laminating an HDPE membrane onto the waterproof blanket, depending on project-specific requirements, to meet the demands of even the most challenging environments—and achieve superior, long-lasting impermeability. The product boasts excellent overall performance, with high tensile and shear strength. The core, sealed-in-place bentonite clay—a non-organic material—expands dramatically upon contact with water, triggering a hydration process that forms a virtually impenetrable, gel-like barrier. What’s more, this bentonite possesses remarkable water-retention capabilities, capable of absorbing and holding up to 10 times its own weight in moisture, ensuring permanent waterproofing properties over time.

Keywords:

Detailed description

Product Introduction:

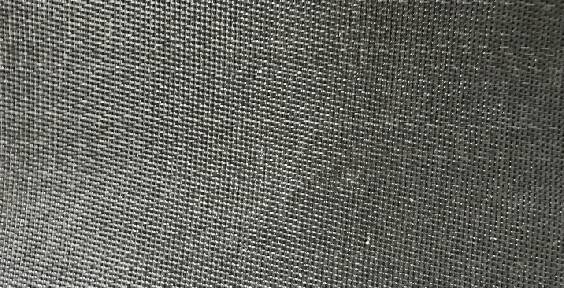

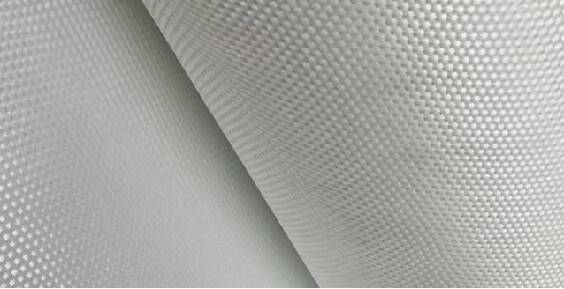

Bentonite Geosynthetic Clay Liner (GCL) is a new type of geosynthetic material designed as an environmentally friendly, eco-friendly composite barrier. It consists of a layer of clay or other low-permeability mineral material encased between geotextiles or geomembranes, joined together through needle-punching or sewing processes. Depending on project requirements, an HDPE membrane can also be bonded onto the waterproof liner to meet the needs of specific environmental conditions, enhancing the overall seepage control performance. This product boasts excellent overall performance, with high tensile and shear strength. The impermeable bentonite layer sandwiched in the middle is an inorganic material that swells dramatically upon contact with water, triggering a hydration process that forms a highly effective, non-permeable gel-like barrier. Additionally, this bentonite possesses remarkable water-retention capabilities, capable of absorbing and holding moisture up to 10 times its own weight—ensuring long-lasting, permanent waterproofing properties.

GCL is a type of impermeable liner that sits between GCL (Geosynthetic Clay Liner, a thick, compacted clay-based barrier) and high-molecular materials like geomembranes. It is primarily used in environmental engineering projects such as waste landfills, underground reservoirs, and subterranean infrastructure construction, effectively addressing issues like sealing, isolation, and leak prevention—while also demonstrating excellent performance and strong resistance to physical damage.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric

ZHONGTAI HENGBANG Engineering & Technology Co., Ltd.

Address: East Section of Zhongtianmen Avenue, Tai'an High-tech Zone, Shandong Province

Service Hotline

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.