-

About UsZHONGTAI HENGBANG Engineering Technology Co., Ltd. is located in the Academician Entrepreneurship Base of Tai'an National High-Tech Industrial Development Zone, Shandong Province. The company is a comprehensive service provider specializing in engineering consulting and design, materials R&D and manufacturing, as well as operations and maintenance. With strong technical expertise and robust R&D capabilities, its products are primarily applied in critical areas such as water conservancy infrastructure projects, transportation infrastructure initiatives, and environmental protection solutions for isolating and preventing leakage from urban waste and highly hazardous industrial solid waste.

-

ProductsZHONGTAI HENGBANG Engineering Technology Co., Ltd. boasts production lines sourced from countries including Germany, Italy, Denmark, Belgium, and Switzerland, adhering to rigorous quality management systems and testing standards. We are equipped with advanced testing equipment capable of evaluating tensile strength, creep resistance, UV protection, water permeability, flame retardancy, antistatic properties, chemical corrosion resistance, and oxidation performance.

-

Application CasesThe product is primarily used in hydraulic infrastructure projects, transportation infrastructure projects, and environmental protection applications—including the isolation and impermeability of municipal waste and highly hazardous industrial solid waste.

-

BlogPrioritizing technological advancement and innovation, our company is committed to fulfilling user needs to the fullest extent possible.

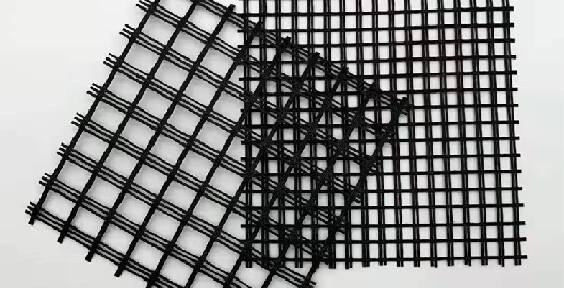

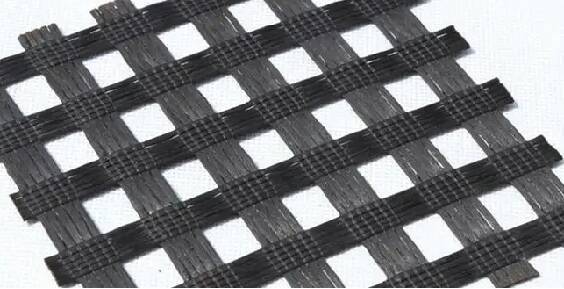

Warp-Knitted Geogrid

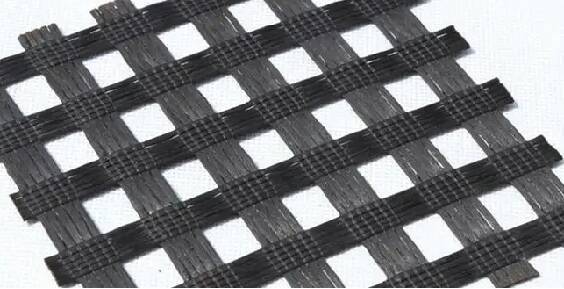

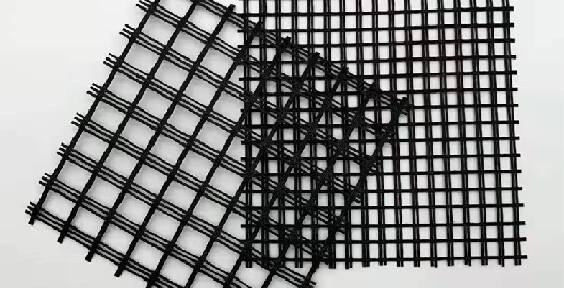

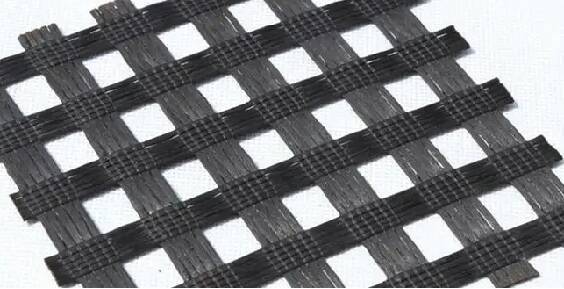

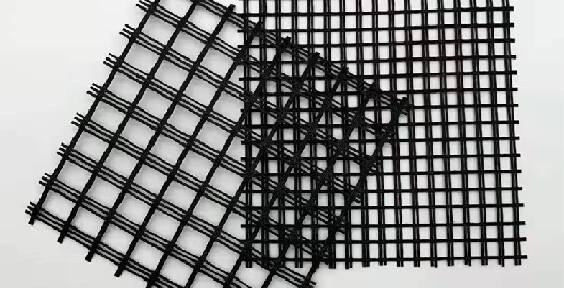

Economically woven geogrids are mesh-like geosynthetic materials manufactured using high-strength polyester (PET) or glass fibers as raw materials, processed through an edging technique (where warp and weft yarns are interwoven and subsequently coated with PVC or modified asphalt). Their unique structure provides exceptional tensile strength and minimal creep characteristics, making them widely used in applications such as soft ground reinforcement, pavement crack prevention, and slope protection—tasks that effectively enhance the overall integrity and deformation resistance of soil structures.

Keywords:

Detailed description

Product Introduction:

Economically woven geogrids are mesh-like geosynthetic materials made from high-strength polyester (PET) or glass fibers, processed through an edging technique (where warp and weft yarns are interwoven and then coated with PVC or modified asphalt). Their unique structure provides exceptional tensile strength and minimal creep, making them widely used in applications such as soft ground reinforcement, pavement crack prevention, and slope protection—tasks that effectively enhance the overall stability and deformation resistance of soil structures.

Product advantages:

High nodal strength for longer-lasting tensile resistance: The warp-knitting process ensures strong interlacing points between the warp and weft yarns, resulting in high tensile strength (20–200 kN/m) and excellent creep resistance even under prolonged loading conditions.

Flexible adaptation, crack-resistant and puncture-proof: The material is pliable, seamlessly conforming to the terrain while distributing stress to minimize cracking in the roadbed. It also resists penetration by sharp objects, safeguarding the underlying structural layers.

Corrosion-resistant and anti-aging, with easy-to-install construction: The surface coating offers superior UV resistance, acid- and alkali-proof properties, and a lifespan exceeding 30 years. Additionally, the roll material is lightweight and can be quickly laid—either mechanically or manually.

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric

ZHONGTAI HENGBANG Engineering & Technology Co., Ltd.

Address: East Section of Zhongtianmen Avenue, Tai'an High-tech Zone, Shandong Province

Service Hotline

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.