Geotextile Pipe Bag

Geotextile tubular bags are manufactured using high-performance, specialized polypropylene monofilament, flat filament, or split-film yarns, followed by precision sewing and shaping. These geotextile fabrics exhibit varying levels of strength and permeability, while also boasting exceptional UV resistance as well as outstanding durability against seawater and microbial erosion.

Keywords:

Detailed description

Geotextile tubular bags are manufactured using high-performance, specialized polypropylene monofilaments, flat filaments, or split-film filaments, which are then specially sewn and shaped into the final product. These geotextile bag fabrics come in various strength and permeability grades, while also offering exceptional UV resistance as well as durability against seawater and microbial erosion.

Applied in a wide range of hydraulic and marine engineering projects, such as bank protection, breakwaters, wave-breaking structures, river and canal rehabilitation, and tubular containment systems—this technology is also used for dewatering industrial waste, sludge treatment, coal mine waste, and agricultural byproducts. Geotube bags are easy to install, and once completed, they offer excellent durability and long-lasting performance.

Geotube manufacturing process: Drawing—Warping—Weaving the greige fabric—Inspection—Sewing—Inspection—Outbound

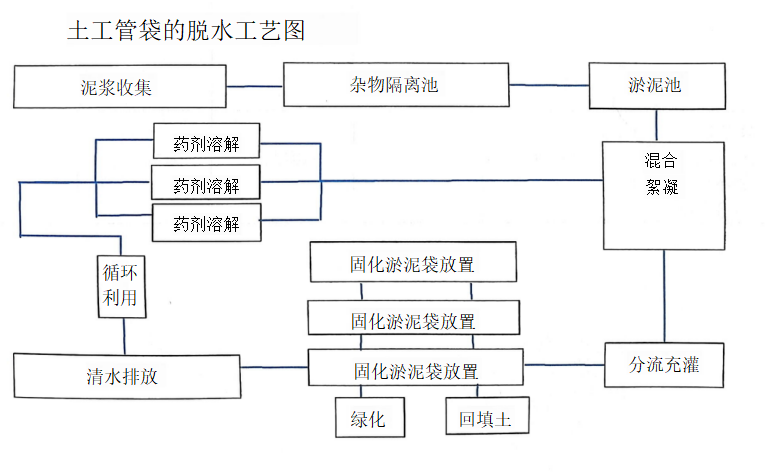

Principle of dewatering with geotube bags: By leveraging the filtering structure of geotextile tube bags and the liquid pressure inside the bag as dual driving forces, the process promotes mud-water separation through the addition of chemicals. As a result, water seeps out of the bag while the sludge remains trapped inside, effectively achieving dehydration and solidification of the sludge. The dewatering process using geotextile tube bags is divided into three distinct stages: filling, dewatering, and consolidation.

Filling: Fill the sludge or mud into geotube bags via pipelines, and if necessary, add a flocculant to accelerate dehydration and promote the consolidation of solid particles.

Dehydration: Clean water flows out of the geotube, and its dewatering process relies primarily on two driving forces: the filtration structure inherent in the geotube material and the liquid pressure inside the bag. Additionally, a dewatering agent can be added to further enhance the rate of water removal. After dewatering, more than 99% of the solid particles remain trapped within the geotube, while the clarified effluent can be collected and recycled back into the system for reuse.

Consolidation: Once the solid particles stored in the geotube have filled up, the geotube and its contents can be disposed of at a landfill, or the consolidated material can be removed and, where appropriate, the geotubes themselves can be reused.

Product Advantages (1) The filter bag volume is freely adjustable over a wide range, offering flexible processing capacity for various projects. (2) No need for dehydration equipment investment, no requirement for electrical power setup, and no need for relocation; (3) The filter bag system requires minimal investment, uses very little manpower, and is easy to operate; (4) The filter bags can be placed at any suitable location along the banks of rivers and lakes, and the clear effluent can be discharged directly into the waterways. (5) The filter bags can be placed at multiple points according to the dredging vessel's operations, making them suitable for in-situ dewatering of sludge. (6) The dewatering process for sludge is conducted as a closed operation, preventing secondary pollution. (7) The moisture content of the sludge inside the bag can be adjusted based on the number of times the filter bag is filled, the pressure applied, and the idle time. (8) Utilizes a special filter cloth with excellent filtration performance, high tensile strength, and resistance to aging. (9) The formulation of the chemical agent can be adjusted according to the condition of the sludge, ensuring its harmless treatment. (10) The dewatered sludge can be used as bank protection soil for rivers and lakes, or as agricultural and landscaping soil. (11) The system engineering requires minimal investment, has low operating costs, and features a short construction timeline. Dimension selection |  |

|

Get a product quote

We’re here to help you every step of the way! Please fill out our inquiry form, and our team will respond promptly.

Recommended Products

Strong technological capabilities and robust R&D expertise

Laminate Film Machine-Woven Fabric